Lathe Cam Software

Samsung scx 4623fw scanner driver. Samsung SCX-4623F DriverSamsung SCX-4623F Printer Driver and Software for Microsoft Windows, Linux and Macintosh.

- Forum Actions

- Quick Links

Thread Tools

Display

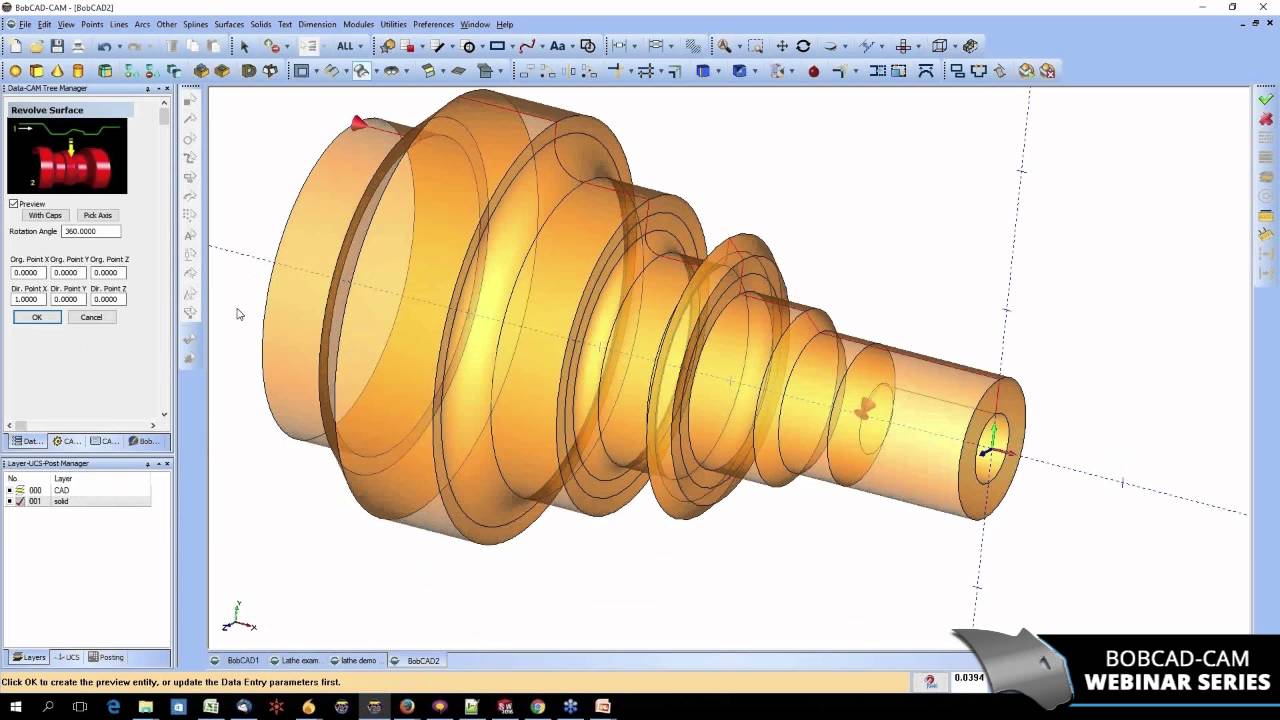

Productivity Advanced solutions for manufacturing. We help connect the largest CAM community worldwide, and our success is a direct result of listening and responding to industry needs for productivity solutions from job set up to job completion. Leader in CNC programming software for Milling, Turning, Routing, Wire EDM. Our CAD-CAM software solution reduces cycle time improving workflow efficiency. PartMaker software for high precision programming for Swiss-type lathes. FeatureCAM software for automated CNC programming. FeatureCAM Ultimate gives you access to the best of both. Mkv video converter free. You can choose between using either PartMaker, FeatureCAM or a combination of the two to suit your needs and preferences.

- Aluminum

- Join Date

- Jan 2013

- Country

- AUSTRALIA

- Posts

- 154

- Post Thanks / Like

- Likes (Given)

- 8

- Likes (Received)

- 9

Lathe software?

- red beardCast Iron

- Join Date

- Apr 2006

- Location

- Grand Rapids, MI USA

- Posts

- 440

- Post Thanks / Like

- Likes (Given)

- 202

- Likes (Received)

- 119

Originally Posted by rick-bI tried it several years ago. I couldn't get it to consistently give good code. Even when it did work it always required a fair amount of editing. In the end it was faster to write the code by hand.

I use OneCNC now, which isn't perfect, but it is much more useful than Kipware. - Aluminum

- Join Date

- Jan 2013

- Country

- AUSTRALIA

- Posts

- 154

- Post Thanks / Like

- Likes (Given)

- 8

- Likes (Received)

- 9

Thanks. I wasn't happy spending the money if it doesn't work, when I spoke to them about it all I really got was 'I may have to buy other software from them to get it to work'. I will have a look at OneCNC.Originally Posted by red beardI tried it several years ago. I couldn't get it to consistently give good code. Even when it did work it always required a fair amount of editing. In the end it was faster to write the code by hand.

I use OneCNC now, which isn't perfect, but it is much more useful than Kipware. - Hot Rolled

- Join Date

- Dec 2003

- Location

- poulsbo, wa, usa

- Posts

- 698

- Post Thanks / Like

- Likes (Given)

- 30

- Likes (Received)

- 286

I have onecnc XR7 for milling and love it , got a free 30 day trial on there lathe software and went back to hand writing code .. once you do a few programs by hand code it gets super simple and fast .. I made up some cheater cards for the most used stuff and can do most programs by hand in under 10 min .. best part is when you write it your self you can go back and edit it super fast and easy .

I would say try the hand code for the first 10 jobs and see how you like it . - doug925Titanium

- Join Date

- Nov 2002

- Country

- UNITED STATES

- State/Province

- Texas

- Posts

- 3,242

- Post Thanks / Like

- Likes (Given)

- 1817

- Likes (Received)

- 800

I love OneCnc on the milling side, though the lathe package left a lot to be desired. With my time / energy / experience with the lathe package, I would not by XR Lathe again...

Hand coding a lathe is so easy, once you understand a few basic G-codes.

I only purchased the lathe cam package, to help my mill guys be able to program lathes.

Oh well.. - aldepoaloStainless

- Join Date

- Mar 2011

- Location

- Clearwater FLA

- Posts

- 1,158

- Post Thanks / Like

- Likes (Given)

- 79

- Likes (Received)

- 234

What is it about the lathe software you didn't like? Calling tools, setting up tools, the posted code, workflow?

- Titanium

- Join Date

- Feb 2007

- Location

- Aberdeen, UK

- Posts

- 3,457

- Post Thanks / Like

- Likes (Given)

- 1207

- Likes (Received)

- 1288

Originally Posted by D.D.Machine..went back to hand writing code .. once you do a few programs by hand code it gets super simple and fast .. I made up some cheater cards for the most used stuff and can do most programs by hand in under 10 min.People make this argument every time someone asks this question.Originally Posted by doug925Hand coding a lathe is so easy, once you understand a few basic G-codes.

The point people overlook is that yes, programming a lathe is simple, if you're making basic turned parts.

There are any number of legitimate reasons to need full blown cam for making turned parts. Complex geometries with contiguous tangent arcs, intricate internal profiles with non-existent tool clearances, non-orthogonal features, profiles generated with double sided or fully profiled inserts, contoured undercuts, the list goes on.

Making toolpaths for lathes by hand is simple, but as soon as the toolpath is no longer the only thing you have to worry about, hand coding lathes gets complicated fast.

I started out programming lathes by hand and was proficient at it, so I can say with some certainty that at least half of the turned parts we do now would be extremely uncomfortable to do by hand.

With all that said, there is a good argument for hand coding lathes if your parts allow it, and a good argument for full cam programming if your parts demand it. I don't see any good argument for software like Kipware, it's expensive for what it actually is - essentially just a macro code generator - and it provides none of the benefits of full cam. Just buy a conversational machine like a Mazak or Hurco, but since Fanuc started bolting manual guide i onto their controls just about every lathe on the market has some form of conversational code generation. - Aluminum

- Join Date

- Jan 2013

- Country

- AUSTRALIA

- Posts

- 154

- Post Thanks / Like

- Likes (Given)

- 8

- Likes (Received)

- 9

I was looking at the software for ease of use mainly. But gregormarwick is right, Kipware does start to get expensive with all the add on's they keep telling me I 'may need' the other thing that is hard to handle is you have no way of testing the software first to see if it is even going to work for my needs. They just keep saying buy it it will be OK. I am a one-man deal and sometimes I just do not have time to hand code everything.

- Hot Rolled

- Join Date

- Dec 2003

- Location

- poulsbo, wa, usa

- Posts

- 698

- Post Thanks / Like

- Likes (Given)

- 30

- Likes (Received)

- 286

Rick

Its not clear from your post if you have spent some time learning how to hand code a lathe program? I spent 30 years hand coding 3 and 4 axis mill parts and well I do most parts with Onecnc the last few years I still do finger cam a couple times a week on the mills , Lathe code is super easy after doing mill code for years and yes I was like you and looked for a simple , good and easy to use lathe cam package , but even in the $3,500 price range I found nothing that worked vary good or vary easy . I went back to finger cam on the lathe code and well its not my choice to do it by hand it works and is cheap. There is some Haas manuals on Lathe programming put out like 10 years ago that are GREAT.. there new manuals are not as good , I got copys of the older one off ebay for like 30 bucks and use it a lot .

Most programming manuals seem to be for milling and then they kinda add a few pages to them and call it a lathe manual also , the 'OLD' Haas lathe manual is lathe only. - Aluminum

- Join Date

- Jan 2013

- Country

- AUSTRALIA

- Posts

- 154

- Post Thanks / Like

- Likes (Given)

- 8

- Likes (Received)

- 9

My hand G-coding is only very basic, that has a lot to do with just having the time at the moment. In the shop here I have a CNC mill and a lathe but off-site, I have 2 CNC plasmas a CNC bender and a CNC bandsaw and all seem to use different forms of G-code, sometimes there is just not enough time in the day to get good at any one of them.Originally Posted by D.D.MachineRick

Its not clear from your post if you have spent some time learning how to hand code a lathe program? I spent 30 years hand coding 3 and 4 axis mill parts and well I do most parts with Onecnc the last few years I still do finger cam a couple times a week on the mills , Lathe code is super easy after doing mill code for years and yes I was like you and looked for a simple , good and easy to use lathe cam package , but even in the $3,500 price range I found nothing that worked vary good or vary easy . I went back to finger cam on the lathe code and well its not my choice to do it by hand it works and is cheap. There is some Haas manuals on Lathe programming put out like 10 years ago that are GREAT.. there new manuals are not as good , I got copys of the older one off ebay for like 30 bucks and use it a lot .

Most programming manuals seem to be for milling and then they kinda add a few pages to them and call it a lathe manual also , the 'OLD' Haas lathe manual is lathe only.

I was hoping for an easy way out, but it's looking more and more like the Kipware-T is not the way to go so far I have not found one person who has had it or has bought it and been happy with it. - red beardCast Iron

- Join Date

- Apr 2006

- Location

- Grand Rapids, MI USA

- Posts

- 440

- Post Thanks / Like

- Likes (Given)

- 202

- Likes (Received)

- 119

I will agree with you that OneCNC mill is much better than OneCNC lathe. It seems like they put a lot more resources into making and improving the mill software than the lathe. (I imagine there are a lot more mill users than lathe users.)Originally Posted by doug925I love OneCnc on the milling side, though the lathe package left a lot to be desired. With my time / energy / experience with the lathe package, I would not by XR Lathe again...

Hand coding a lathe is so easy, once you understand a few basic G-codes.

I only purchased the lathe cam package, to help my mill guys be able to program lathes.

Oh well..

I'm decent at hand coding lathes, but once I got used to OneCNC lathe, learned all of the tricks and workarounds for things that it doesn't do right, and got my posts refined, I got pretty quick at writing programs with it. On simple programs I probably save a few minutes per program and it's much faster for more complex contours than hand coding. The other nice thing about it is I have two turning centers that both use slightly different code. If I make a program for one machine, and I need to run that job in the other machine the next time, I just have to switch to the other post-processor and repost the program.

If I wasn't already familiar with OneCNC Mill the learning curve would have been pretty high, but to be honest, I couldn't really find any thing else out there in the price range. It seemed to be my best option in a group of mediocre (at best) options. I realize that this isn't a glowing review, and it isn't meant to be. It has potential if OneCNC invests in it like they have with the mill software, but I'm not sure that they will ever do that. It works for me as it is, but it certainly could be better.

- Site Areas

- Forums

- Manufacturing Today

- Specific Machine Forums

- Open Discussion

- Commerce

- Machinery Manual, Brochure and Photo Archives

- Forum features

Tags for this Thread

Bookmarks

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

Simple Lathe Cam

- BB code is On

- Smilies are On

- [IMG] code is On

- [VIDEO] code is On

- HTML code is Off